Dubai WoodShow is a platform for wood specialists in the Middle East to connect with global businesses. UAE-based Desert Board will be at the premier show to promote its cutting-edge technologies and demonstrate why mass timber could be construction’s answer to sustainability.

Table of Contents

Mass timber is slowly gaining ground as a sustainable source for the global construction industry. As timber-framed buildings are proving popular viable alternatives to traditional materials, the focus will shift next month to the United Arab Emirates.

While the Emirate is a relative newcomer to the mass timber trend, cutting-edge technologies in the wood industry landscape, such as Desert Board’s groundbreaking Palm Strand Boards (PSBs), will be showcased at the 20th Dubai Wood Show from March 5-7.

But what is mass timber construction, and how is Desert Board becoming one of the prime movers in leading the transition away from traditional materials in the Middle East?

Types of Mass Timber

Mass timber is engineered wood where layers of planks are crossed over each other to offer an exceptionally strong and load-bearing structure. They are significantly lighter and can be utilized to construct big buildings. The results are a range of sustainable architecture solutions and eco-friendly structures.

Mass timber construction can come in a variety of different specs. The most popular and widely used mass timber product is cross-laminated timber (CLT). This is created by stacking wood in alternating directions and bonding them together with structural adhesives.

Dowel-laminated timber (DLT) is an all-wood joinery approach formed by stacking softwood lumber panels that are friction-fitted together with hardwood dowels.

Nail-laminated timber (NLT) is timber sheets stacked and fastened with nails, while glue-laminated timber, or Glulam, is composed of wood laminations bonded with durable, moisture-resistant adhesives. The laminate grains run parallel with the length of the wood member.

Hybrid mass timber systems can also be adopted in construction. These refer to a combination of wood, steel, concrete, and other materials in the building.

Mass timber products offer great flexibility and can serve as beams, columns, floors, roofs, and walls, depending on the directional strength of each wood product.

Benefits

As mass timber is a low-carbon footprint construction alternative, it works as a carbon sink and reduces greenhouse gas emissions.

One of the biggest advantages of mass timber is the speed and efficiency that components can be utilized to construct. Mass timber construction can be done off-site, shipped, and installed, ensuring quicker construction planning times and reduced project downtime.

Mass timber not only offers greater adaptability to the design of a building and enhances the urban landscape, but it also offers an excellent strength-to-weight ratio and additional thermal, acoustic, and fire-resistant benefits. And with faster construction potential, mass timber can save on time and cost and result in minimal waste.

For the end user, a modular, healthy, natural building can add to the aesthetic look of an urban landscape. Importantly, it can be used to decarbonize buildings as a natural fiber has sequestered CO2.

As an eco-friendly building material, mass timber acts as a carbon sink, absorbing and storing carbon dioxide from the atmosphere. By utilizing mass timber, architects and developers can reduce carbon emissions and mitigate the impact of climate change.

Buildings of Mass Timber

Sustainable living is being enhanced each year as more and more mass timber buildings sprout across the planet. From Canada to Japan, these buildings are about 20% lighter than traditional buildings.

The 18-storey Brock Commons residential tower at Vancouver’s University of British Columbia was completed in 70 days in 2017 and was then the world’s tallest wood building. A year previous, the seven-storey T3 office block in Minneapolis was finished in less than ten weeks and became the tallest building in the US.

In 2020, a 19-storey mixed-used property called Terrace House, using mass timber, was completed by the Vancouver-based development firm PortLiving. Several other projects have been completed since, such as the 6-storey T3 Goose Island in Chicago and an 11-storey, 500,000-square-foot mass timber building in Newark, New Jersey.

The Hotel Magdalena in Austin, Texas, became the first hotel in the US to be built using mass timber. In a lifecycle assessment against a baseline design made entirely of concrete, dowel-laminated timber, and Glulam had 38% less global warming potential.

Buildings with sustainable urban development materials are also gaining ground in Nordic countries, Western Europe, and Asia. Wooden buildings are rising across Tokyo, Japan, including the AEAJ Green Terrace, which secured the “Grand Prize” in the Tokyo Metropolitan Government-sponsored “Wood City Tokyo Model Architecture Awards”. The three-storey hybrid building is the new home of the Association Aroma Environment Association of Japan.

Innovating on Wood in the UAE

With mass timber becoming a trending global movement to transition to bio-based wood materials, the UAE is becoming one of the leaders in the Middle East for such change.

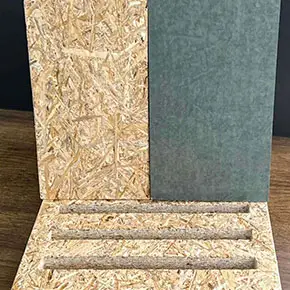

Desert Board is part of that growing pivot in advocating green building materials through the use of its innovative PSBs. Their process involves bio-based palm fronds being delivered to the plant and then turned into small biomass parts processed with pressure and heat with glue and wax being applied.

The end product offers high performance, durability, and a local decarbonized durable solution. The solution is considered a carbon sink as the sequestered carbon exceeds the manufacturing footprint. For every m3 board with 800 kg density, the retained carbon sink contribution of the board is 401 kg of CO2e for the entire lifetime use of the board.

The board is designed for 100-plus years of durability and to ensure a long life and circular economy; there is also a take back and reuse/recycled program in place for local customers.

The company has created double-storey buildings from their PSBs and used beams made of their boards to highlight that it can be utilized as a mass timber component.

Matthias Gelber, Desert Board’s Brand Ambassador, said: “Can we turn cities into sequestered carbon structures? It offers a golden opportunity to bring nature back into the home, and people love to see exposed wood structures. Nature is close to us and can help boost human mental health.

“The product that should be the first choice for developers for mass timber in the UAE and the broader Middle East should be Desert Board’s. Because at the same time, it is deforestation-free. It can be scaled up to walls and floors, and as a mass timber solution, it has incredible benefits, without a single tree being cut.

“Made in the UAE, the climate-resilient building materials are bio-diversity positive and can be adopted in a range of formaldehyde-free modular products. This innovation could be a part of a mass timber revolution in the UAE construction sector.”

Desert Board and other attendees will be bringing the focus of mass timber and woodworking into sharper focus for an estimated 10,000-plus audience at the Dubai WoodShow, which is being hosted at Dubai World Trade Centre. With over 400 exhibitors, it offers abundant opportunities to see how mass timber and wood products are the building materials of the future.