The Emirates Green Building Council is at the heart of efforts by the UAE to enable a more sustainable approach to the built environment. We look at how it is achieving that in light of the recent COP28 event and how one of its members, Desert Board, is championing decarbonization with its approach to eco-friendly building materials at a local level.

The United Arab Emirates (UAE) is among the first nations in the Middle East to take definitive action towards net-zero carbon emissions by 2050. Central to that aim is the Emirates Green Building Council (Emirates GBC), a non-government organization that promotes and educates sustainability in the built environment.

With nearly 150 members, including Desert Board, the EmiratesGBC represents thousands of individuals involved in initiatives that include furthering the use of green building materials across the UAE and the region.

Table of Contents

Action on built environment emissions

The Council’s focus on the UAE’s built environment and the need for low carbon footprint construction was a main highlight of the recent COP28 in Dubai. The built environment overall is responsible for about 37% of energy use, 39% of CO2 emissions, and 40% of material use globally.

Adopting a sustainable built environment that protects and enhances people, places, and the natural environment and tackles the climate crisis can have several advantages. Implementing sustainable architecture solutions and using eco-friendly building materials in the constructed environment would improve quality of life, gradual economic expansion, and the cultivation of enhanced local skills and job opportunities.

At COP28, Emirates GBC launched the UAE Sustainability Built Environment Blueprint, which is committed to the transition of the built environment sector in the UAE. Her Excellency Razan Al Mubarak, the UN Climate Change High-Level Champion for COP28 and Managing Director of the Environment Agency Abu Dhabi said: “Buildings and the construction sector are at the nexus of both the challenge and solution of climate change.”

Due to be revealed in detail at the Sustainable Cities in Action Forum at Expo City Dubai on March 5-6, the blueprint aims to map local developers’ challenges and help unlock greater climate action.

According to its third Nationally Determined Contribution (NDC), a plan of action the country is required to declare publicly, the UAE wants to reduce net greenhouse gas emissions from a previously targeted figure of 208 metric tonnes of Carbon dioxide equivalent (MtCO2e) to 182 MtCO2e(Reference).

The building sector is expected to deliver 85% of the reductions by 2030.

UAE’s NDC will advise on new policy initiatives to decarbonize the building sector. These include revising building codes to improve the efficiency of new buildings, introducing building energy labels, scaling up retrofitting, and accelerating the installation of energy-efficient cooling applications.

COP28 signified a turning point for the construction industry, symbolizing a more assertive commitment to using climate-resilient building materials and improving sustainable living aims.

Desert Board’s Input

Leading businesses in the UAE have raised their ambitions to decarbonize the built environment and utilize best practices in pledging to cut footprints across scopes 1, 2, and 3 to net zero by 2050 and halve emissions by 2030.

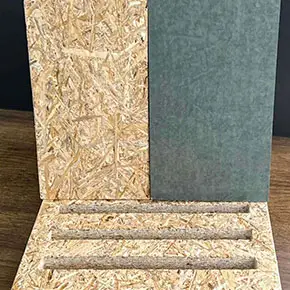

Desert Board is among these leaders seeking to minimize carbon emissions by developing sustainable urban development materials. As a sustainable wooden board manufacturer, the company repurposes palm bio-mass into eco-friendly building materials. Its locally-sourced and fire-resistant boards offer a nature-based solution while promoting responsible and sustainable practices.

Its unwavering commitment to sustainable construction materials was brought to global attention at a panel discussion at a COP28 event hosted in association with the Emirates GBC.

The panel comprised chairperson Dr Beatrix Henkel; Ali Said, GM, Holcim UAE; Kamal Farah, Director, Desert Board; Matthias Gelber, Desert Board’s Brand Ambassador; Rami Alsodi, Senior Engineering Researcher, DPW Sharjah, and Muna Alqaysi, Manager, Architectural Permit and Sustainability Section Ports Customs and Free Zone Corporation.

During the discussion, Gelber showcased Desert Board’s products as perfect examples of a local carbon sink circular building material and a viable solution for companies serious about lowering the carbon footprint of any building, structure, or interior fit-out.

In championing Desert Board as an innovator in the UAE construction sector, Gelber said the company offers a local decarbonized durable solution. It derives biomass to value rather than going to landfill, potentially converting it into methane, contributing to high greenhouse emissions. Desert Board is preventing those methane emissions by turning the biomass into high-performance formaldehyde-free materials.

Gelber was also excited the UAE’s government and private sector was serious about supporting the mission of COP28 with practical actions.

With local and international inputs from a lively audience, the discussion drew several conclusions that demonstrated that the topic of global Greenhouse Gas Emission reduction and mitigation was now of high importance.

“It is evident producers of building materials in the UAE are putting major efforts into lowering their carbon footprints,” emphasized Gelber, who was voted Greenest Person on the Planet in 2008 and who used to chair the Middle East CSR summit regularly,

Desert Board uses natural fiber containing biogenic carbon. It is considered a carbon sink as the sequestered carbon is higher than the manufacturing footprint calculated via a third-party LCA study. For each m3 board with 800 kg density, the retained carbon sink contribution of the board is 401 kg of CO2e for the full lifetime use of the board.

The board is designed for 100-plus years of durability and to ensure a long life and circular economy; there is also a take back and reuse/recycled program in place for local customers.

He said: “Combined with such a circular waste material derived from a nature-based solution, there are additional efforts to reduce the manufacturing carbon footprint.

“One other aspect I love about the product is its biodiversity-enhancing nature. No tree has to be cut, no mining is needed, and the habitat of animals is preserved and not impacted by the production process. The naturally available strands and leaves from the tree that are discarded are used as Desert Board’s raw material.”

He added that government support is needed to enhance demand for circular and low-carbon products. In some cases, standards need to be changed to enable a different cement formation if there is a traditional restriction that might be based on cement clinker content rather than the end product’s performance.

Gelber reflected: “It is essential to support further decarbonization and growth of available solutions for the built environment. In some cases, the initial volume production of low-carbon building materials might be more expensive, so it is critical to scale this up so that price points can be reached and be accepted by the wider market.

“For this, procurement and standards should favor low-carbon solutions. We hope buyers and the government will prefer materials like Desert Board’s that reduce the carbon footprint of new construction projects and fit-outs in the UAE.”

While recognized UAE developers are beginning to consider various factors on their decarbonization journeys, Desert Board is already providing a scalable and viable local solution. By advocating and supporting the extensive efforts of the Emirates GBC, Desert Board and the UAE construction industry can contemplate a low carbon future.