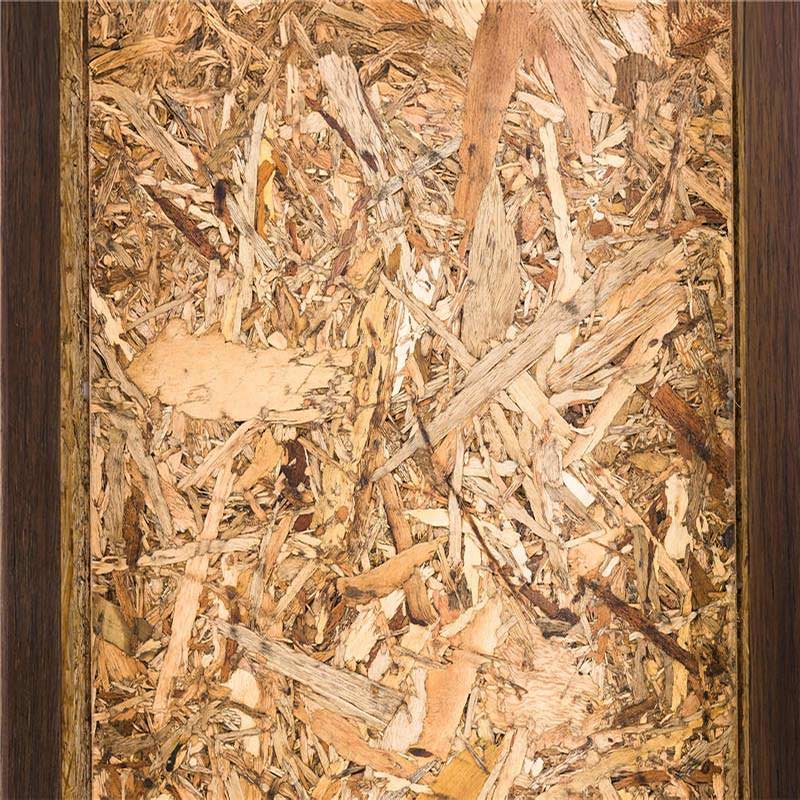

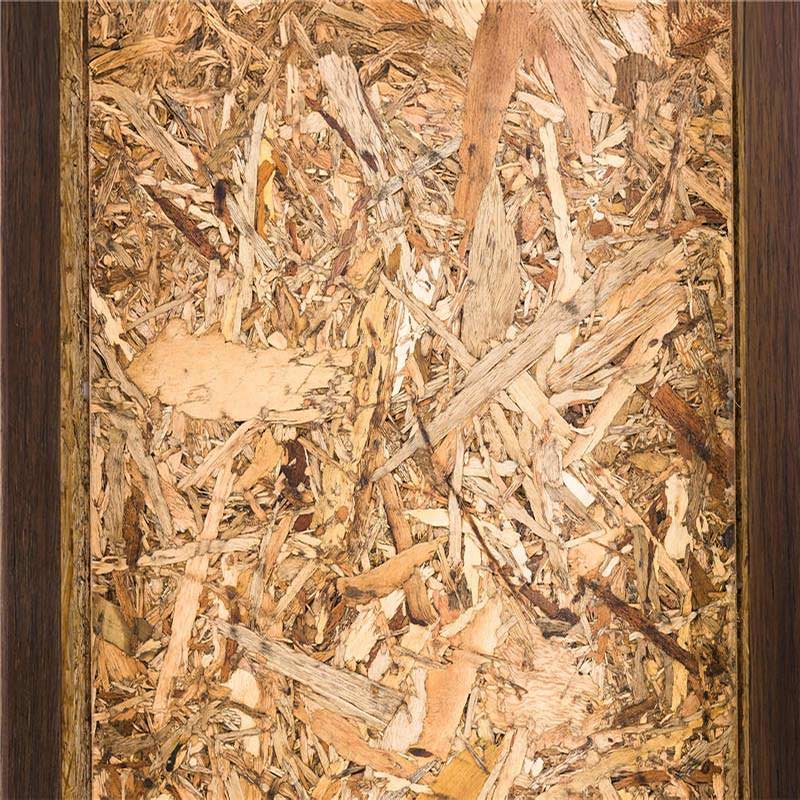

Why PSB® EcoCore Supreme

Specifications

| Modulus of Rupture | 14 N/mm2 |

|---|---|

| Modulus of Elasticity | 3,500 N/mm2 |

| Internal Bonding | 0.26 N/mm2 |

| Thickness Swelling | 15% |

| Width | 1,200 – 1,250 mm |

| Length | 1,830 – 3,048 mm |

| Thickness | 30 – 38 mm |